With a wide range of products, increasingly stringent customer requirements, and old systems, the company is facing challenges in terms of personnel, equipment, production, quality, and operations. It needs to improve the overall efficiency of the plant to ensure the company's sustained competitive advantage and improve its core competitiveness.

? A large amount of work is done manually, with high personnel costs.

? Outdated equipment management system with no predictive alarms. Frequent abnormalities, reducing OEE. ? Quality problems cannot be pinpointed and solved quickly.

? The management system does not introduce big data model support, lack of ability to give management decision-making suggestions, low decision-making efficiency.

? Old production system, cumbersome.

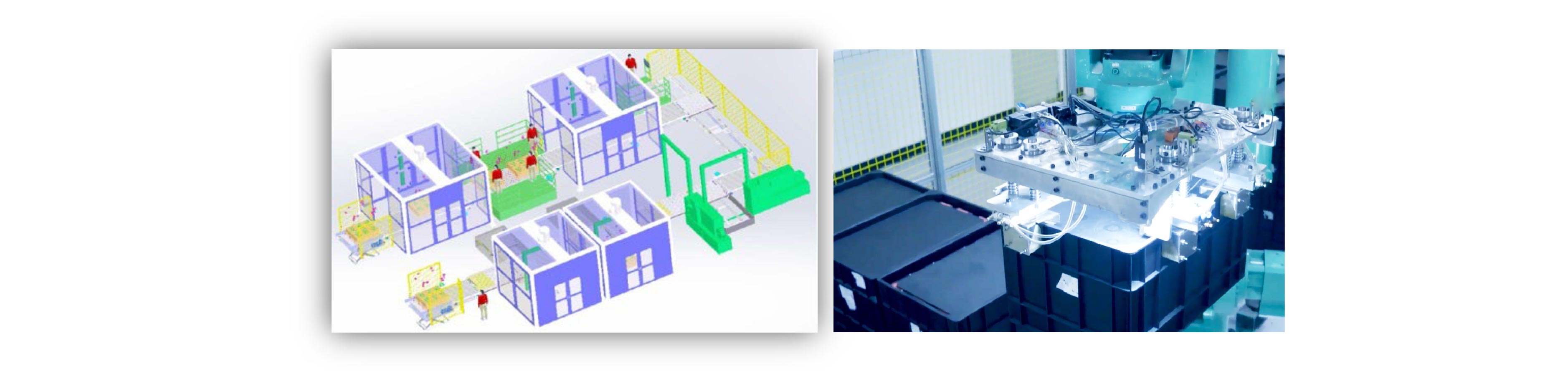

? By encouraging staff innovation and strengthening smart work culture, build a smart factory from top to bottom through the OT+IT work style and cross-group coordination and cooperation.

? Warehouse management: mobilize AGV systems to enable automatic transportation of finished products across floors and buildings, improve the efficiency of material supply, prevent material mixups, and build an intelligent warehouse management system.

? Equipment operation & maintenance: based on TPM system, loT technology and big data models, real-time collection of equipment data is used to build a comprehensive smart equipment management system.

? Production management: MES + loT + big data modelling. Real-time collection of production, materials, equipment, personnel data to form a complete traceability closed-loop helps to eliminate defects, improve product quality, standardize production process, improve efficiency, and comprehensively utilize personnel and equipment.

? Quality Assurance: Based on QMS system, the quality management system of big data model, realizing comprehensive intelligent quality management.

? Decision-making support: based on the visualization in the smart manufacturing dashboard, big data models are used to provide decision-making data support and decision-making recommendations to achieve accurate decision-making.

? Inventory levels decreased by 25%, storage area reduced by 30%, material supply efficiency increased by 150%, and instances of mixing and incorrect materials increased by 100%.

? Defect rate reduced by 30%, production efficiency increased by 30%, and production manpower decreased by 20%.

? Re-inspection manpower decreased by 95%, defective product leakage rate reduced by 30%, and inspection manpower decreased by 20%.

? Maintenance time reduced by 20%, abnormal downtime reduced by 30%, OEE increased by 15%, and equipment management costs reduced by 10%.

? Decision-making efficiency increased by 50%, abnormal handling time reduced by 40%, and production yield increased by 30%.